[About TOP GIN] [TOP GIN Milestones] [Injection Molding Machine] [Air Compressor] [Pump] [Ceramic]

[Chiller] [Others]

【Application Products】

Blower are widely used in chemical fertilizer, metallurgy, petrochemical, food, oil, building materials, cooling towers, mines, tunnel engineering, textile, gas stations, large and small ships inflatable and propulsion, air conditioning equipment, dust extractors, boilers and industrial furnaces Kiln ventilation system, household appliances in the ventilation, sewage treatment… etc..

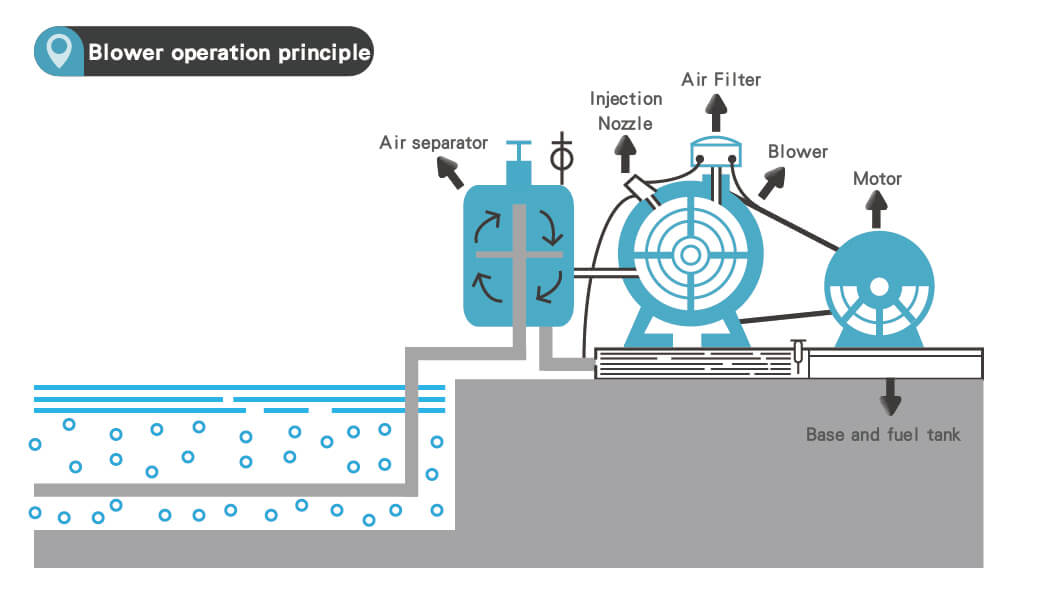

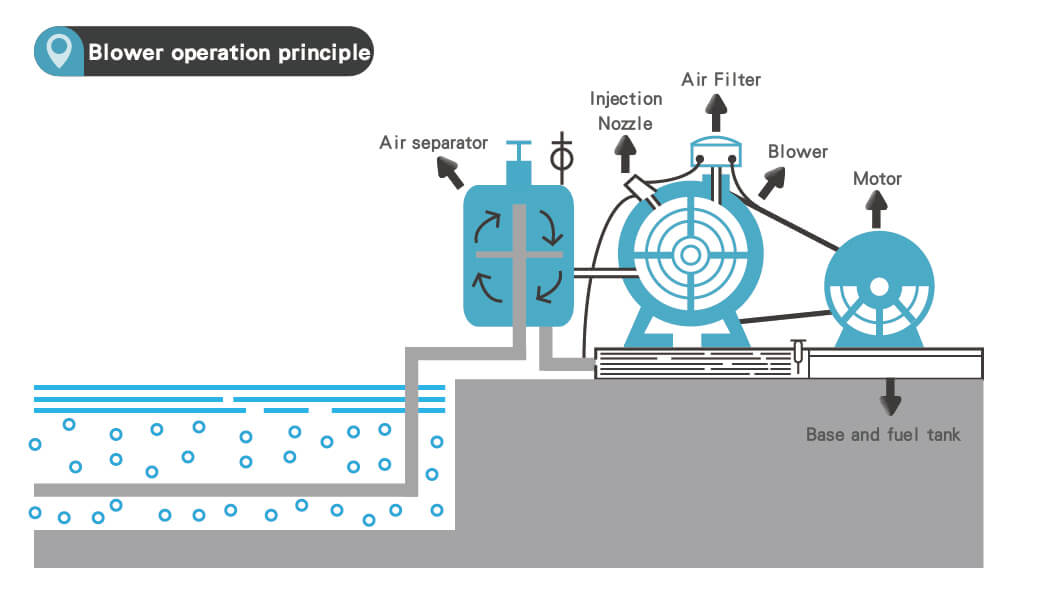

【Operating Principle】

Mainly by the blower body, drip nozzle, air filters, motors, air separators, base and tank composition. The blower is eccentrically operated by the biased rotor in the cylinder and causes the volume change between the blades in the rotor slot to suck, compress, and discharge the air. Operation, the use of the blower pressure difference, automatically run to the drip nozzle, drip into the cylinder to reduce friction and noise, while maintaining the gas cylinder does not return.

【Characteristics】

Blower is the compression and transport of air machinery, the air pressure is called a small fan, the larger for the blower, blower types are: centrifugal fan, Francis fan, axial fan ... and so on, in which the centrifugal Type fan the most widely used, but the start-up time is longer, starting current, about 6 to 8 times the rated current, the mechanical impact of the motor and fan, thus affecting the life of the fan, mechanical properties and pump quite similar , But the fan's no-load torque is much smaller than the pump, so the low-speed operation, the energy-saving space than the pump, if the use of variable frequency energy-saving module to improve, reduce energy consumption and improve production efficiency is the industry to reduce costs, improve an effective approach to price competitiveness of products.

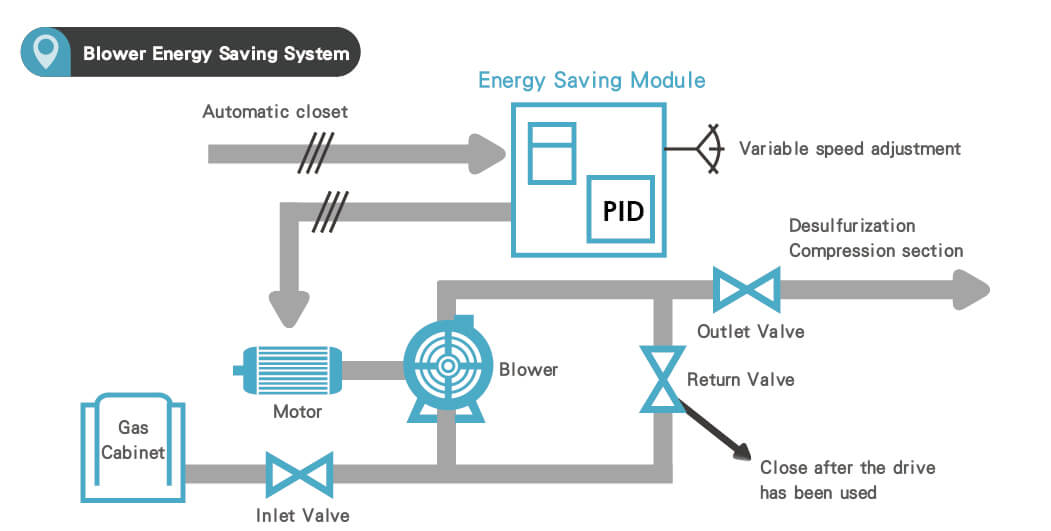

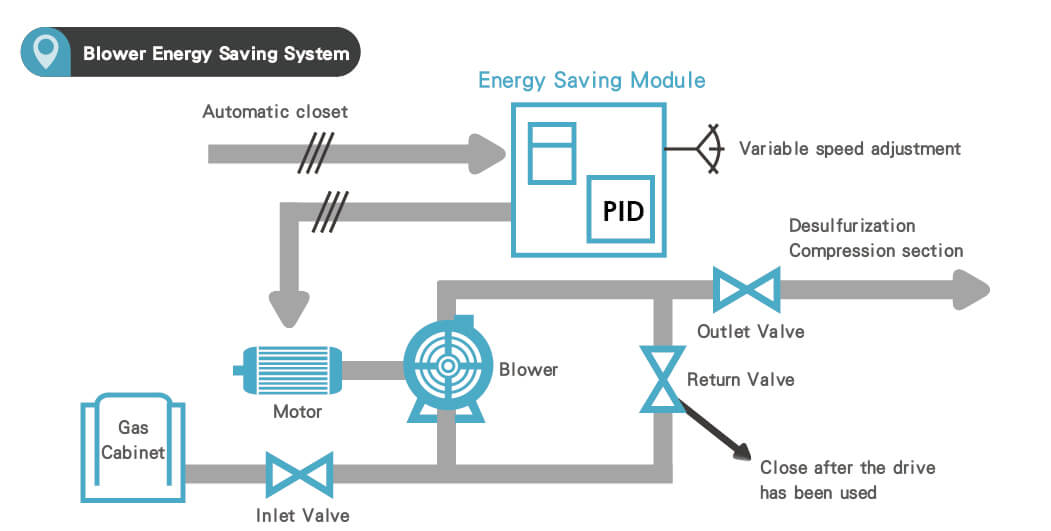

【Energy Saving Method】

【Energy Saving Analysis】

[Chiller] [Others]

【Application Products】

Blower are widely used in chemical fertilizer, metallurgy, petrochemical, food, oil, building materials, cooling towers, mines, tunnel engineering, textile, gas stations, large and small ships inflatable and propulsion, air conditioning equipment, dust extractors, boilers and industrial furnaces Kiln ventilation system, household appliances in the ventilation, sewage treatment… etc..

【Operating Principle】

Mainly by the blower body, drip nozzle, air filters, motors, air separators, base and tank composition. The blower is eccentrically operated by the biased rotor in the cylinder and causes the volume change between the blades in the rotor slot to suck, compress, and discharge the air. Operation, the use of the blower pressure difference, automatically run to the drip nozzle, drip into the cylinder to reduce friction and noise, while maintaining the gas cylinder does not return.

【Characteristics】

Blower is the compression and transport of air machinery, the air pressure is called a small fan, the larger for the blower, blower types are: centrifugal fan, Francis fan, axial fan ... and so on, in which the centrifugal Type fan the most widely used, but the start-up time is longer, starting current, about 6 to 8 times the rated current, the mechanical impact of the motor and fan, thus affecting the life of the fan, mechanical properties and pump quite similar , But the fan's no-load torque is much smaller than the pump, so the low-speed operation, the energy-saving space than the pump, if the use of variable frequency energy-saving module to improve, reduce energy consumption and improve production efficiency is the industry to reduce costs, improve an effective approach to price competitiveness of products.

【Energy Saving Method】

- The wind resistance characteristics will change with the throttle opening, the fan power consumption is proportional to the amount of wind power, so through the throttle shut down to reduce the amount of wind, the consumption of electric power will be reduced, but this control method has the disadvantage of Waste of electricity and fuel, noisy, and consume a large number of workers labor, with a large range of power load adjustment, the air blower due to changes in boiler load and often inefficient state, but also a lot of energy wasted in the air duct baffle.

- Fan characteristics will change with the speed, the fan is a quadratic load, the consumption of electrical power and speed of the cube is proportional to the use of variable frequency energy saving module speed, built-in advanced power electronic devices IGBT and multi-level topology Circuit and sine wave PWM modulation vector control strategy, through the processor control, can have a fixed frequency and three-phase AC power system for power conversion, resulting in adjustable frequency and current with the load of high-voltage AC system, which can fan To achieve continuous speed, reduce energy consumption.

【Energy Saving Analysis】

- Saving electricity costs about 30% to 60%.

- Energy-saving air compressor module does not change the original working conditions, to ensure that the fan and its electronic parts life.

- There are over-current, overload, over-voltage, owed to 53 kinds of protection mechanisms.

- The use of automatic control, without human care and re-adaptation.

- Has two mechanisms, frequency and mains mode switch, the first time self-clarify the anomaly, lifting the customer's problems.

[About TOP GIN] [TOP GIN Milestones] [Injection Molding Machine] [Air Compressor] [Pump] [Ceramic]

[Chiller] [Others]

.jpg)

.jpg)

[Chiller] [Others]

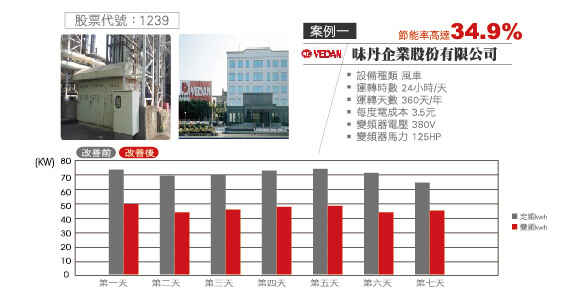

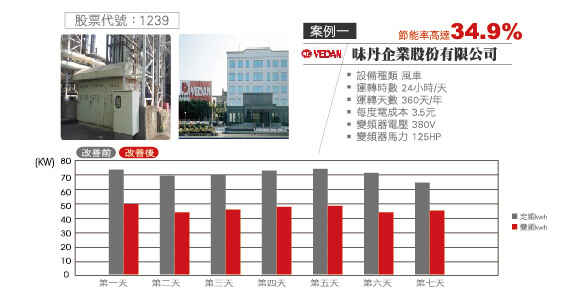

- Vedan company / Energy-saving of ceramic of Ventilation Equipment / Energy-saving rate: 34.9%

.jpg)

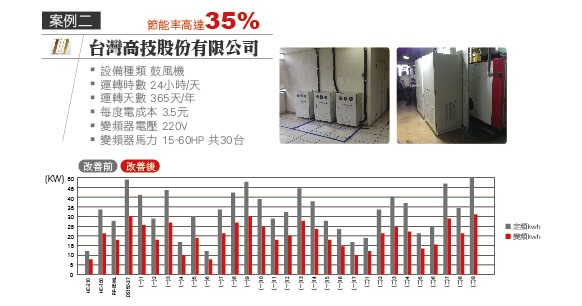

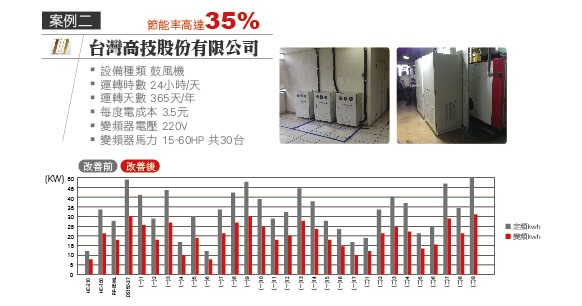

- Global Hi-Tech / Energy-saving of ceramic of Ventilation Equipment / Energy-saving rate: 35%

.jpg)

Energy saving of windmill and dust collection equipment

Energy saving of dust collection equipment

Energy saving of windmill and dust collection equipment