Injection Molding Machine

/

Energy Solution

【Application Products】

Various devices such as plastic injection molding machine, die casting machine, blown film machine, oil hydraulic press, extruder, pulverizing machine, extrusion machine, sealing and cutting machine, molding machine, film blowing machine, waving machine, hollow molding machine and hydraulic press.

[About TOP GIN] [TOP GIN Milestones] [Chiller] [Air Compressor] [Pump] [Ceramic]

[Ventilation system] [Others]

1.【Application Products】

Various devices such as plastic injection molding machine, die casting machine, blown film machine, oil hydraulic press, extruder, pulverizing machine, extrusion machine, sealing and cutting machine, molding machine, film blowing machine, waving machine, hollow molding machine and hydraulic press.

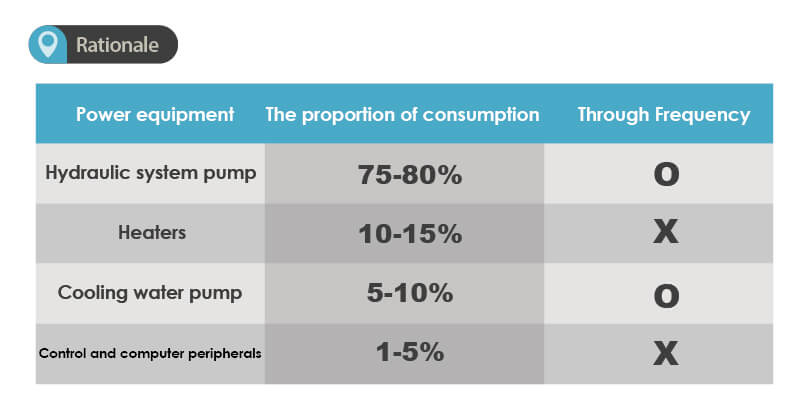

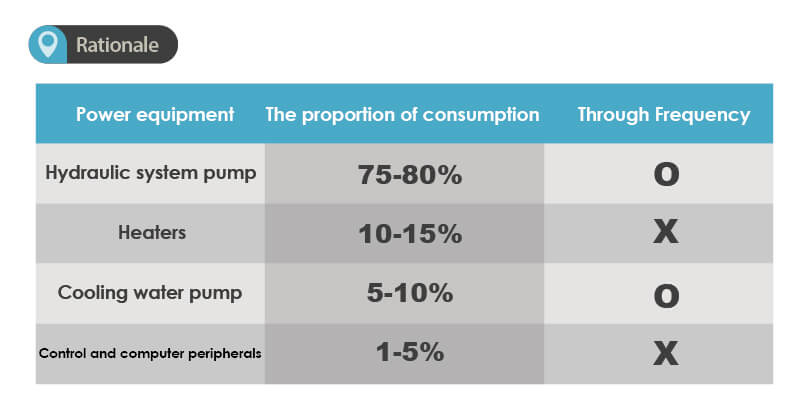

2.【Basic Principles】

The energy consumption of the injection molding machine may be briefly divided into four parts:

3.【Advantages of Energy saving Modules】

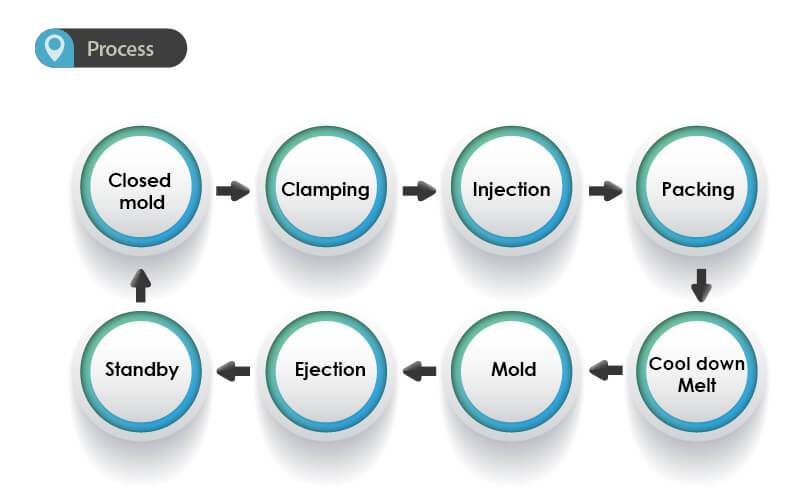

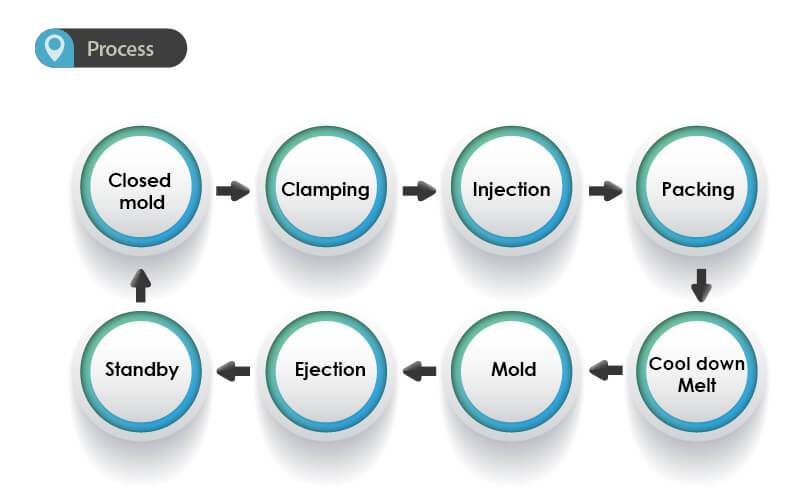

4.【Procedure of Injection Molding】

● For the process of injection molding, energy consumption during the process of plastic injection and plastic melting (plastic feeding) is highest; however, that during the process of pacing, cooling and standby is relatively lower. Power consumption of hydraulic oil pump makes up more than 75 percent of overall power consumption of injection machine. Because the quantitative oil pump injection molding machine can only provide fixed amount of oil while the oil supply for most injection machines is larger than demands, a great amount of surplus high-pressure hydraulic oil flows backwardly through a relief valve and the energy is waste. Meanwhile, as the oil temperature has increased during the process of compression, a large amount of energy is wasted by the high-temperature oil and each valve is thus worn out. Moreover, the extra energy consumed by the water cooling system for cooling down the high-temperature oil is also wasted.

● The energy-saving controller of quantitative pump injection machine is reconfigured. Based on the setting panel of the injection machine, the speed and pressure setting on the panel are converted into 0 to 10 voltage signal or 4 to 20mA current signal. The energy-saving box of the injection machine may control the speed of oil pump’s motor based on the setting and adjust the oil output of each modeling oil pump to meet the actual demands. By reducing the overflowing to the minimum, the energy may be saved.

[Ventilation system] [Others]

1.【Application Products】

Various devices such as plastic injection molding machine, die casting machine, blown film machine, oil hydraulic press, extruder, pulverizing machine, extrusion machine, sealing and cutting machine, molding machine, film blowing machine, waving machine, hollow molding machine and hydraulic press.

2.【Basic Principles】

The energy consumption of the injection molding machine may be briefly divided into four parts:

- Power consumption of hydraulic oil pump is more than 75 percent of that of injection molding machine. The oil supply and the operational speed is fixed and unchangeable, yet the oil demands during the process of injection molding is floating. Installation of energy-saving module which controls the operation speed of a motor through the pressure flow may prominently reduce the power consumption and increase efficiency.

3.【Advantages of Energy saving Modules】

- Using Top Gin Energy saving Module to save 25 to 65 percent of the overall power consumption, increasing efficiency, accelerating return on investment.

- Decreasing starting current of a motor which is more prominent as the power generation machine supplies power.

- Hydraulic oil temperature obviously decreases (5 to 15°C), which extends the life of oil seals and decreases the consumption of cooling water.

- Smooth operation may eliminate hydraulic impact and efficiently decrease noise and the accident rate of equipment.

- Shorting the production cycle and increasing production efficiency under a certain molding conditions

- The operation methods after reconfiguration are identical, reeducation is not necessary.

- It can be switched from an variable to commercial power. It can be switched to commercial power as long as the controller is abnormal or the responsibility is unclear. For the abnormal inverter, it can be dismantled for maintenance without affecting commercial power control and production capacity.

- Signal source of injection machine: voltage DC 0~10V; current (0~1A, 0~2A, 0~3A, 0~4A, 0~5A )

- Energy saving module provides optional intensity. The intensity can be adjusted for different parameters of module and fitting the character of each hydraulic pump (vane pump, gear pump). The AC reactor (ACL) and DC rector (DCL) can also be attached to suppress power low frequency harmonic wave and prevent from interference. The power factor may be improved while the employees may keep away from the poor work environment.

4.【Procedure of Injection Molding】

● For the process of injection molding, energy consumption during the process of plastic injection and plastic melting (plastic feeding) is highest; however, that during the process of pacing, cooling and standby is relatively lower. Power consumption of hydraulic oil pump makes up more than 75 percent of overall power consumption of injection machine. Because the quantitative oil pump injection molding machine can only provide fixed amount of oil while the oil supply for most injection machines is larger than demands, a great amount of surplus high-pressure hydraulic oil flows backwardly through a relief valve and the energy is waste. Meanwhile, as the oil temperature has increased during the process of compression, a large amount of energy is wasted by the high-temperature oil and each valve is thus worn out. Moreover, the extra energy consumed by the water cooling system for cooling down the high-temperature oil is also wasted.

● The energy-saving controller of quantitative pump injection machine is reconfigured. Based on the setting panel of the injection machine, the speed and pressure setting on the panel are converted into 0 to 10 voltage signal or 4 to 20mA current signal. The energy-saving box of the injection machine may control the speed of oil pump’s motor based on the setting and adjust the oil output of each modeling oil pump to meet the actual demands. By reducing the overflowing to the minimum, the energy may be saved.

[About TOP GIN] [TOP GIN Milestones] [Chiller] [Air Compressor] [Pump] [Ceramic]

[Ventilation system] [Others]

● YUEKI INDUSTRIAL / Energy-saving of injection machine / Energy-saving rate: 32%

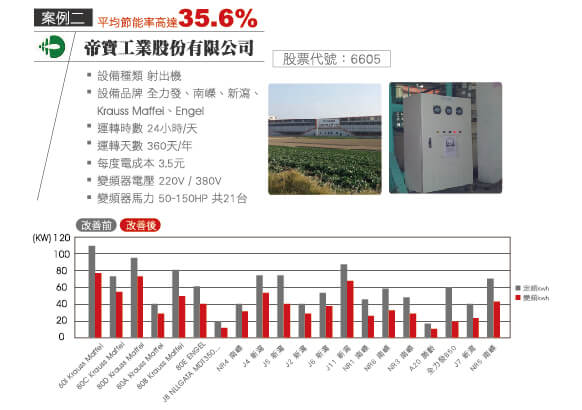

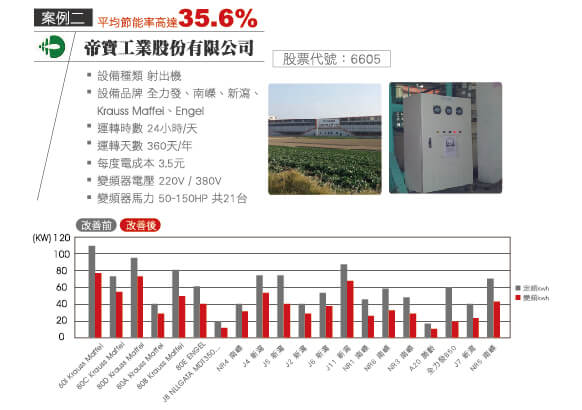

● DEPO car lamp / Energy-saving of injection machine / Energy-saving rate: 35.6%

● SANYANG / Energy-saving of injection machine / Energy-saving rate: 36%

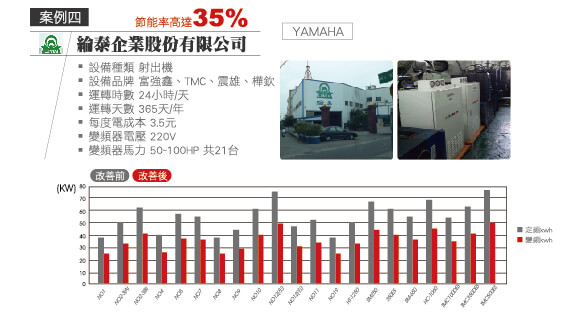

● LUNTAI ENTERPRISE / Energy-saving of injection machine / Energy-saving rate: 35%

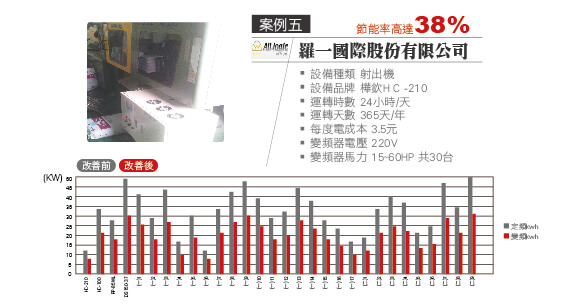

● All-Logic / Energy-saving of injection machine / Energy-saving rate: 38%

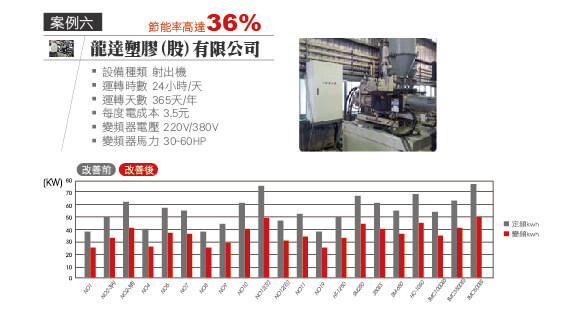

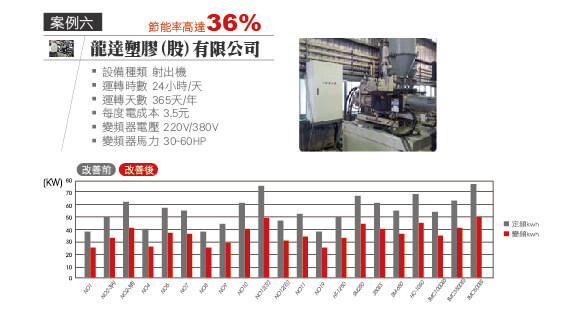

● LONG DAR PLASTIC / Energy-saving of injection machine / Energy-saving rate: 36%

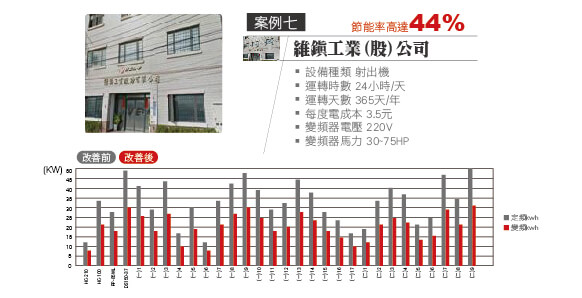

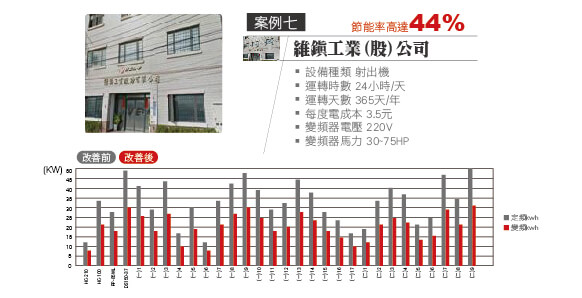

● VELO ENTERPRISE / Energy-saving of injection machine / Energy-saving rate: 44%

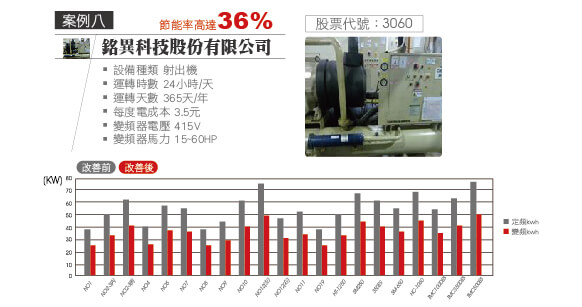

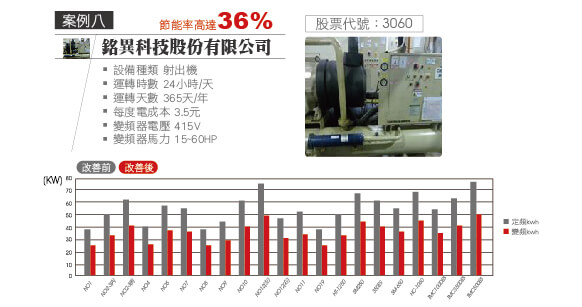

● Min Aik Technology / Energy-saving of injection machine / Energy-saving rate: 36%

[Ventilation system] [Others]

● YUEKI INDUSTRIAL / Energy-saving of injection machine / Energy-saving rate: 32%

● DEPO car lamp / Energy-saving of injection machine / Energy-saving rate: 35.6%

● SANYANG / Energy-saving of injection machine / Energy-saving rate: 36%

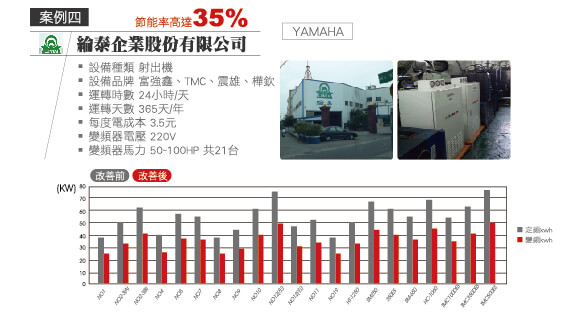

● LUNTAI ENTERPRISE / Energy-saving of injection machine / Energy-saving rate: 35%

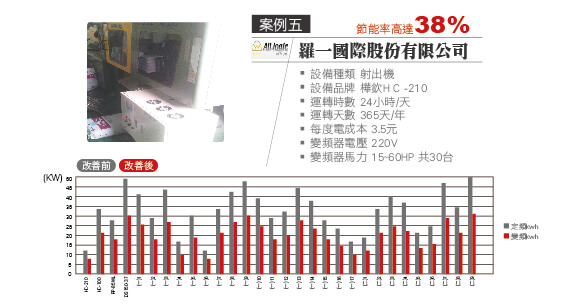

● All-Logic / Energy-saving of injection machine / Energy-saving rate: 38%

● LONG DAR PLASTIC / Energy-saving of injection machine / Energy-saving rate: 36%

● VELO ENTERPRISE / Energy-saving of injection machine / Energy-saving rate: 44%

● Min Aik Technology / Energy-saving of injection machine / Energy-saving rate: 36%

Injection molding machine-Energy saving technology

Energy saving of plastic injection molding machine

Inverter operation of LIEN FA 607CS plastic injection molding machine

Inverter operation of WHA CHIN 400T plastic injection molding machine

Inverter operation of SHUENN JAAN 120T plastic injection molding machine

Inverter operation of 350T injection machine

Energy-saving operation of YC T450 injection machine

Energy-saving operation of YC 600T injection machine

Energy-saving operation of YC 180T injection machine

Energy-saving operation of HC 800-1 injection machine

Energy-saving operation of HC 800 injection machine

Energy-saving data comparison of HC injection machine

Energy-saving data comparison of HC 210T-2 injection machine

Energy-saving data comparison of HC 210T injection machine