Pump

/

Energy Solution

【Application Products】

A pump is mainly applied on wastewater treatment, heating system, compressing devices and air conditioning circulating system. It is because that the power consumption of pumps makes up 20 percent of global power consumption and distributes around various transmission system, the installation of the pump system with energy-saving module may save 30 to 50 percent of energy consumption.

[About TOP GIN] [TOP GIN Milestones] [Injection Molding Machine] [Air Compressor] [Chiller] [Ceramic]

[Ventilation system] [Others]

1.【Application Products】

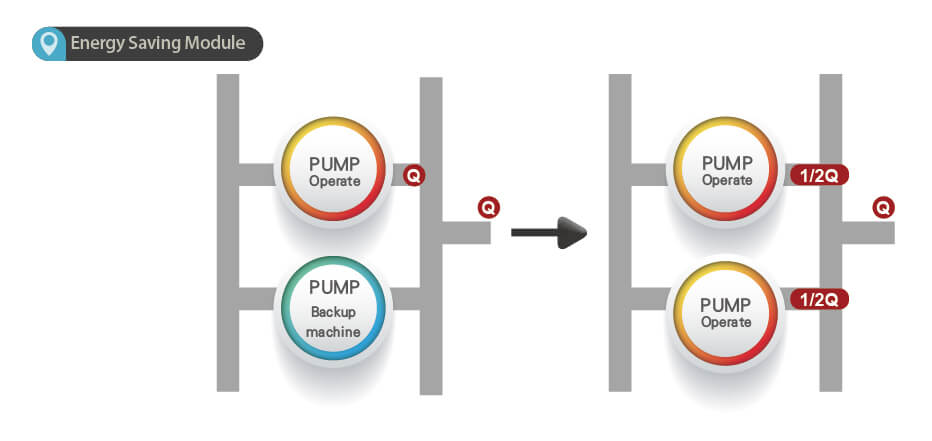

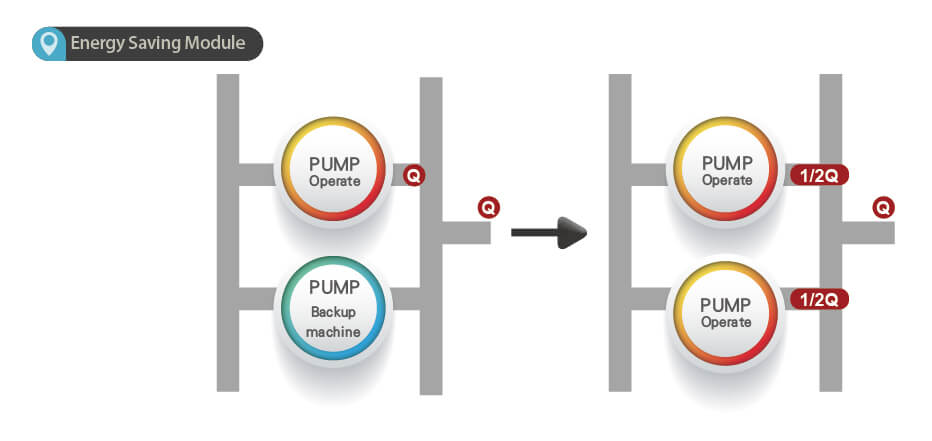

Original Design: two water pumps, one is fully operating (providing the required flows) while the other is a backup machine.

[Ventilation system] [Others]

1.【Application Products】

- A pump is mainly applied on wastewater treatment, heating system, compressing devices and air conditioning circulating system. It is because that the power consumption of pumps makes up 20 percent of global power consumption and distributes around various transmission system, the installation of the pump system with energy-saving module may save 30 to 50 percent of energy consumption.

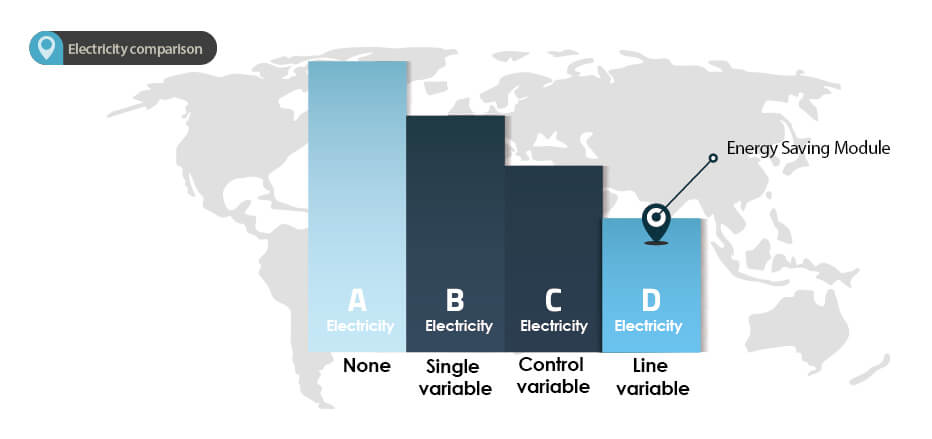

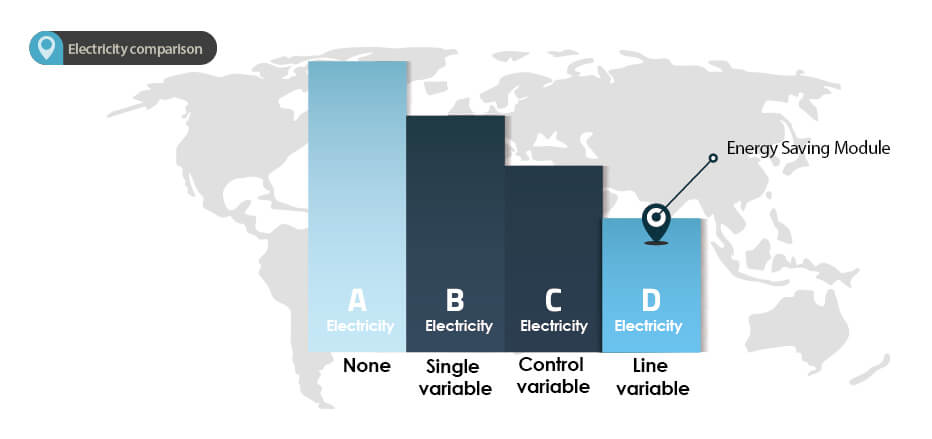

- Traditional Operation: A pump drives a motor with commercial power (60HZ) and adjusts the output flow or pressure required by a throttle valve, which lead to a great amount of power waste.

- Variable: Changing the revolution of motor by inputting the power driving motor with different frequency, which may replace the surplus output flow or pressure required by a throttle valve.

- None (without installing an inverter)

- Single variable (installing an inverter, decreasing to the fixed frequency)

- Controlled variable (installing an inverter and introducing control mechanism for floating frequency).

- Line variable (energy-saving module, installing backup machine for joint control, saving energy with systemic concept).

Original Design: two water pumps, one is fully operating (providing the required flows) while the other is a backup machine.

- Parallel Inverter: The required water flow of the original design is Q and power consumption is P. After the energy-saving system is installed, the two water pumps may reduces the operation speed by 50 percent, providing 0.5 Q water flow respectively (the flow is in direct proportion to the revolution of a motor), 2 x 0.5Q = Q; it shows that the provided flow is identical. The revolution of the water pumps decreases to 50 percent, power consumption is only 0.125P (power consumption is in direct proportion to cubic revolution of a motor, 0.5 x 0.5 x 0.5 = 0.125). After the energy-saving system is installed, the power consumption of the two simultaneously operating water pumps is 0.125P x 2 = 0.25P. Compared to the power consumption of the original design P, the installed energy-saving system helps to save 75 percent of power consumption (P – 0.25P = 0.75P).

Energy saving of pump