[TG600 Current Vector Inverter] [TG900 Variable Load Drive] [TG1000 High Frequency Inverter]

- TG700 servo controller IP contains starting torque compensation (way of inputting the load detection value)

- Blackout management control (operating with storage battery)

- Multi-speed operation (the maximum is 9 speeds)

- Automatic zigzag acceleration and deceleration operation

[TG600 Current Vector Inverter] [TG900 Variable Load Drive] [TG1000 High Frequency Inverter]

【Specification】

|

Output characteristics |

Standard 220 class |

L15 | L20 | L30 | L50 | L75 | L100 | L150 | L200 | L300 | L400 | L500 | L600 | L750 | L1000 |

|

Motor (KW) |

0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 | 55 | 75 | |

|

Inverter capacity (KVA) |

2.3 | 2.5 | 4.3 | 6.8 | 9.9 | 13.5 | 19.5 | 24.5 | 37.5 | 51 | 62 | 70 | 85 | 110 | |

|

Rated output current (A) |

6 | 8 | 11 | 18 | 26 | 34 | 50 | 65 | 96 | 132 | 163 | 183 | 224 | 330 | |

|

Motor rated current (A) |

3.3 | 6.2 | 8.5 | 14 | 19.6 | 26.6 | 39.7 | 53 | 77.2 | 105 | 131 | 160 | 190 | 260 | |

|

The maximum output voltage |

Three-phase 200~240V (corresponding to input voltage) |

||||||||||||||

|

Reated output frequency |

400Hz | ||||||||||||||

|

Power supply |

Reated onput voltage and frequency |

Three-phase 200~240V 50/60Hz |

|||||||||||||

|

Allowable voltage fluctuation |

+10%,-15% | ||||||||||||||

|

Allowable frequency fluctuation |

±5% | ||||||||||||||

|

Output characteristics |

Standard 380/440 class |

H15 | H20 | H30 | H50 | H75 | H100 | H150 | H200 | H300 | H400 | H500 | H600 | H750 | H1000 |

|

Motor (KW) |

0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 | 55 | 75 | |

|

Inverter capacity (KVA) |

2.6 | 3.7 | 4.7 | 6.7 | 12 | 16 | 21.5 | 26 | 41.5 | 52 | 62 | 75 | 98 | 130 | |

|

Rated output current (A) |

3.4 | 4.8 | 6.2 | 8 | 14.5 | 21 | 28 | 34 | 54 | 67 | 80 | 98 | 128 | 165 | |

|

Motor rated current (A) |

1.6 | 3.1 | 4.2 | 7 | 9.8 | 13.3 | 19.9 | 26.5 | 38.6 | 52.3 | 65.6 | 79.7 | 95 | 130 | |

|

The maximum output voltage |

Three-phase 345~480V (corresponding to input voltage) |

||||||||||||||

|

Reated output frequency |

400Hz | ||||||||||||||

|

Power supply |

Reated onput voltage and frequency |

Three-phase 380~440V 50/60Hz |

|||||||||||||

|

Allowable voltage fluctuation |

+10%,-15% | ||||||||||||||

|

Allowable frequency fluctuation |

±5% | ||||||||||||||

|

Control characteristics |

Control mode |

High carrier wave, sine wave PWM, vector control |

|||||||||||||

|

Frequency control range |

0.1~ 400Hz | ||||||||||||||

|

Frequency accuracy (temperature change) |

Digital signal: ± 0.01% (-10 ~ + 40 ℃) Analog signal: ± 0.1% (25 ℃ ± 10 ℃) |

||||||||||||||

|

Frequency setting resolution |

Digital signal: 0.1Hz Analog signals: 0.06Hz / 60Hz |

||||||||||||||

|

Frequency output resolution |

0.01Hz | ||||||||||||||

|

Overload capacity |

150% of rated current for 1 minute |

||||||||||||||

|

Analog frequency setting signal |

DC 0~+10V (20KΩ),4-20mA(250Ω) | ||||||||||||||

|

Deceleration time |

0.01 to 3600 seconds (acceleration, deceleration time set individually) |

||||||||||||||

|

Brake torque |

About 20% (125% loaded brake controller) |

||||||||||||||

|

V / F curve |

Select from 15 types of fixed V/f patterns or set any V/f pattern. |

||||||||||||||

|

Protective function |

Motor protection |

Electronic thermal relay protection |

|||||||||||||

|

Instantaneous overcurrent |

More than 300% of rated output current |

||||||||||||||

|

Fuse FusingProtection |

The motor stops running after the fuse blows |

||||||||||||||

|

Overload |

150% in one min., 200% in ten sec. |

||||||||||||||

|

Overcurrent |

220V-Stops when main-circuit DC voltage is approx. 400V |

||||||||||||||

|

Low voltage |

220V- Stops when main-circuit DC voltage is approx. 220V |

||||||||||||||

|

Instantaneous power-off offset |

Setting when playing power outages than 15ms motor free run to stop |

||||||||||||||

|

Overheat |

Thermistor protection |

||||||||||||||

|

Stall prevention |

Stall prevention during acceleration and deceleration |

||||||||||||||

|

Ground protection |

Electronic circuit protection |

||||||||||||||

|

Charging indication |

The charging indicator turns on when the DC voltage of the main circuit is over 50V |

||||||||||||||

|

Environment |

Venues |

The room is not corrosive or dusty places |

|||||||||||||

|

Ambient temperature |

- 10 ~ + 50 ℃ |

||||||||||||||

|

Storage temperature |

- 20 ~ + 70℃ | ||||||||||||||

|

Humidity |

Below 90% RH (non-condensing conditions) |

||||||||||||||

|

Vibration |

20Hz below: 9.81 M/S (1G), 20 ~ 50Hz :1.96M/S (0.2G) |

||||||||||||||

|

Protective structure |

Wall Mount locking plate inside and take pay type |

||||||||||||||

(Download specification of Inverter TG700)

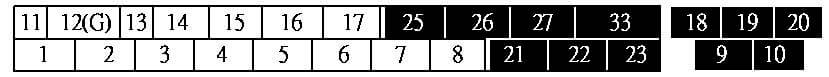

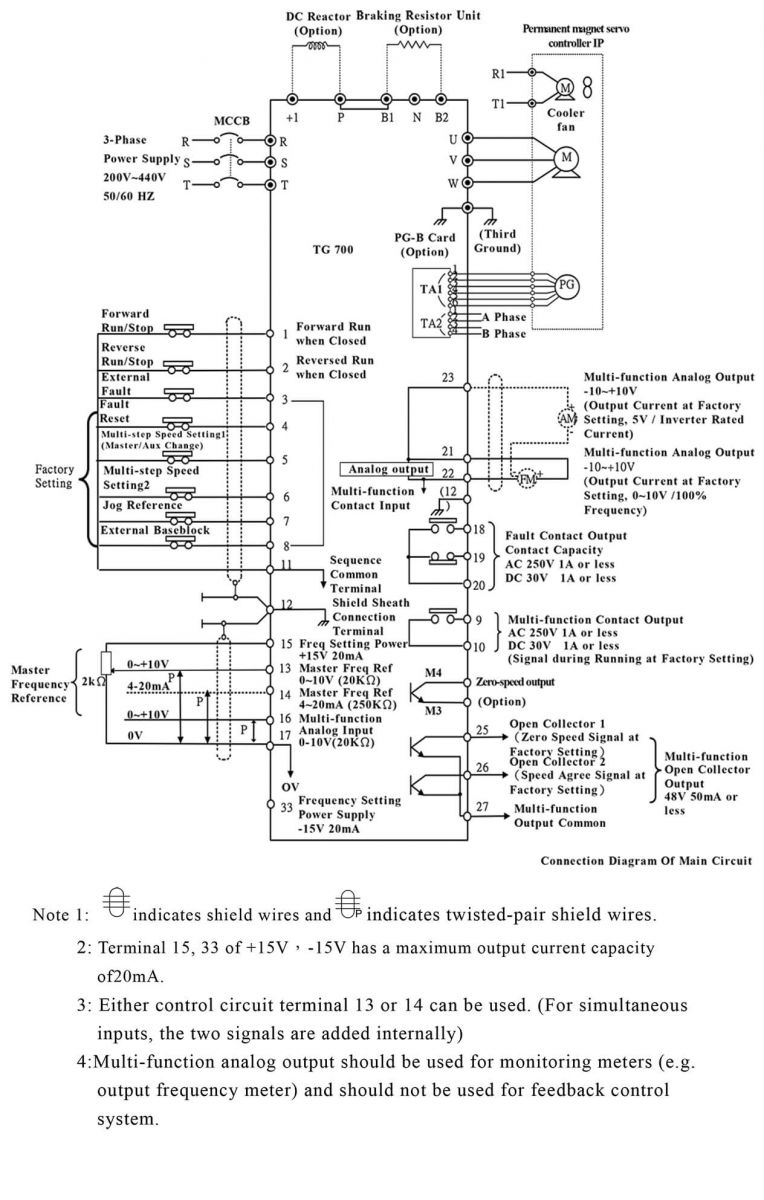

【WIRNG】

● Below is connection diagram of the main circuit and control circuit. Notify the terminal number when wiring.

【STANDARD CONNECTION DIAGRAM( TG700 TYPE)】

● Electric machine with PG wiring by using braking unit and braking resistor unit

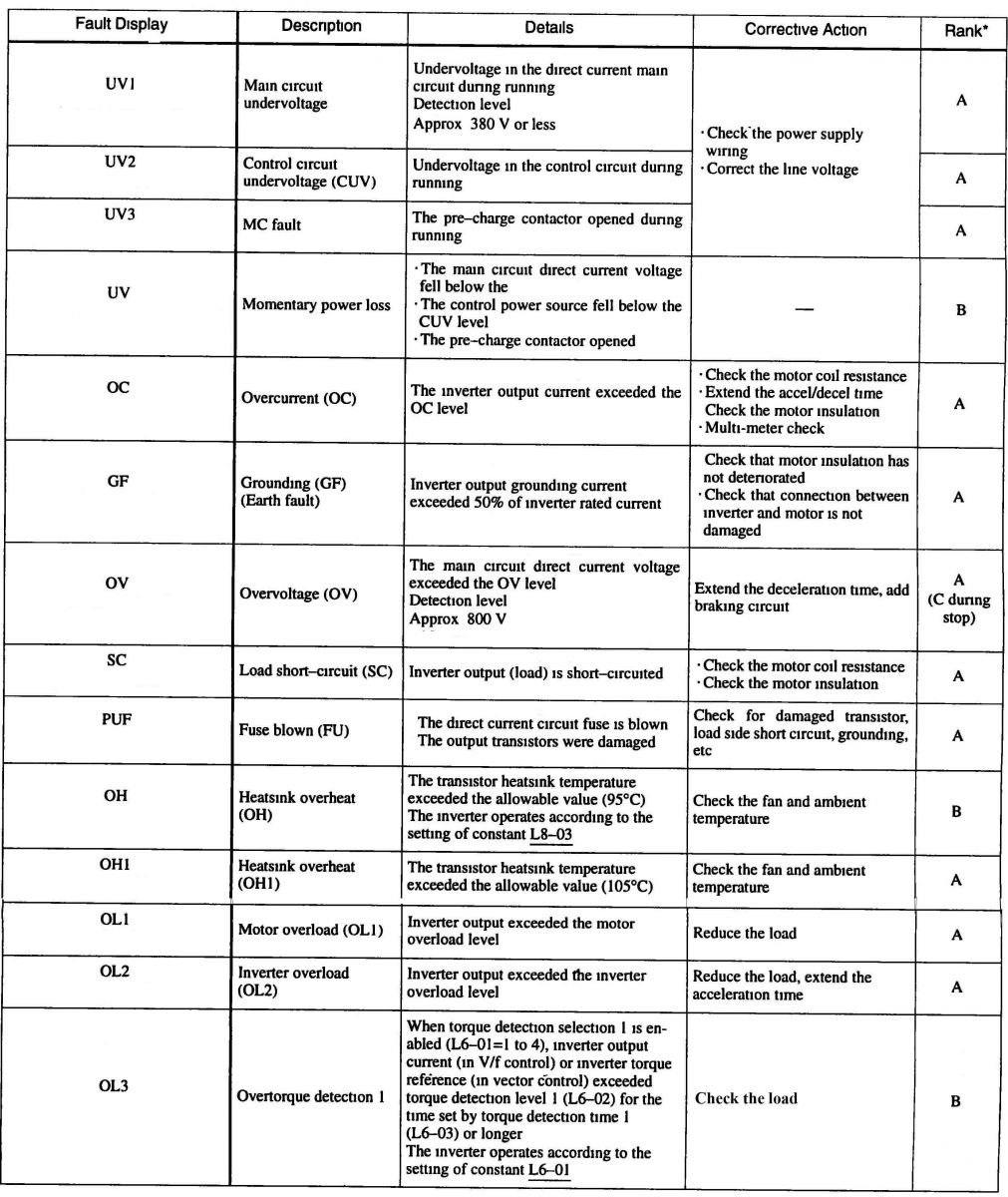

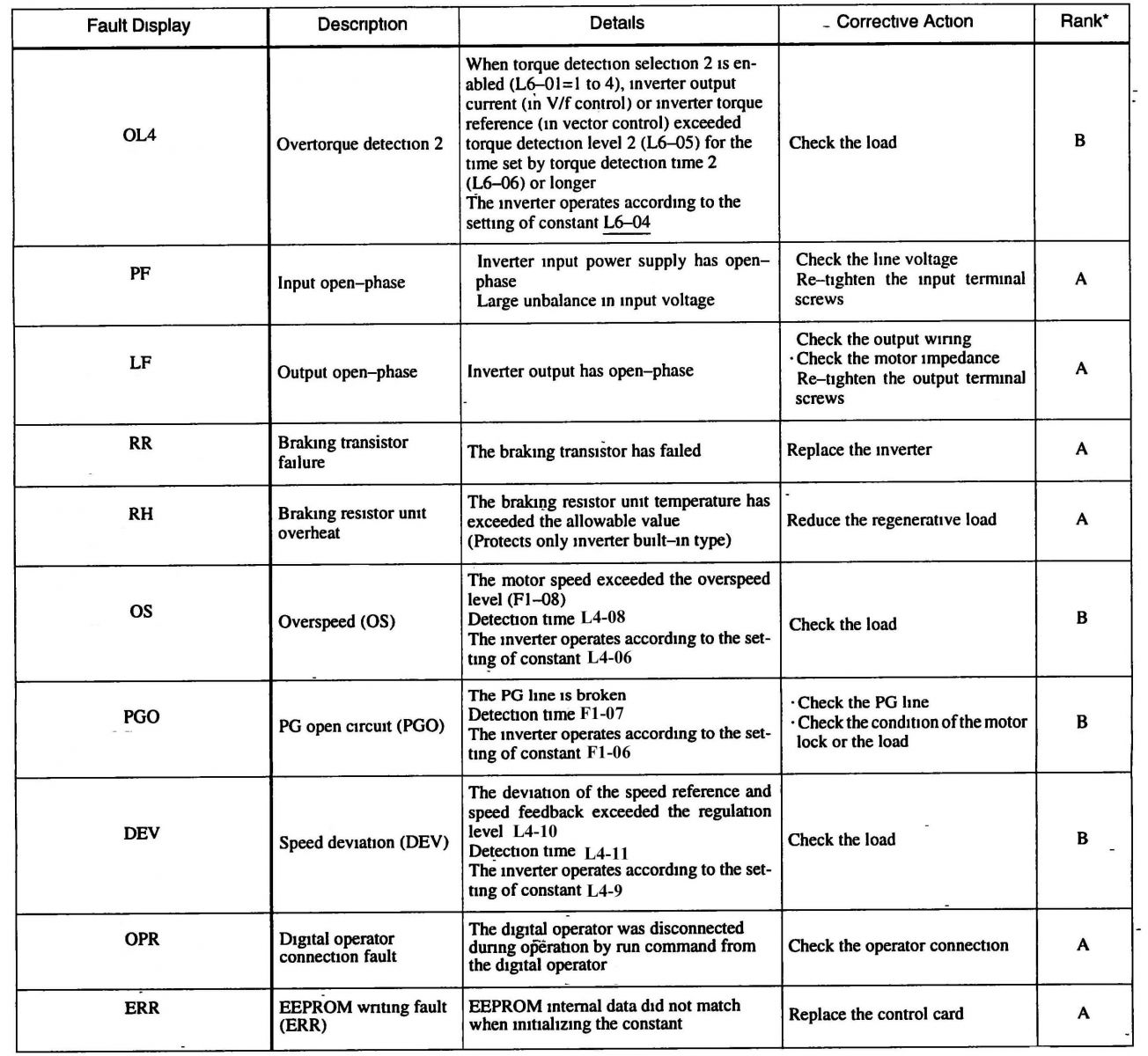

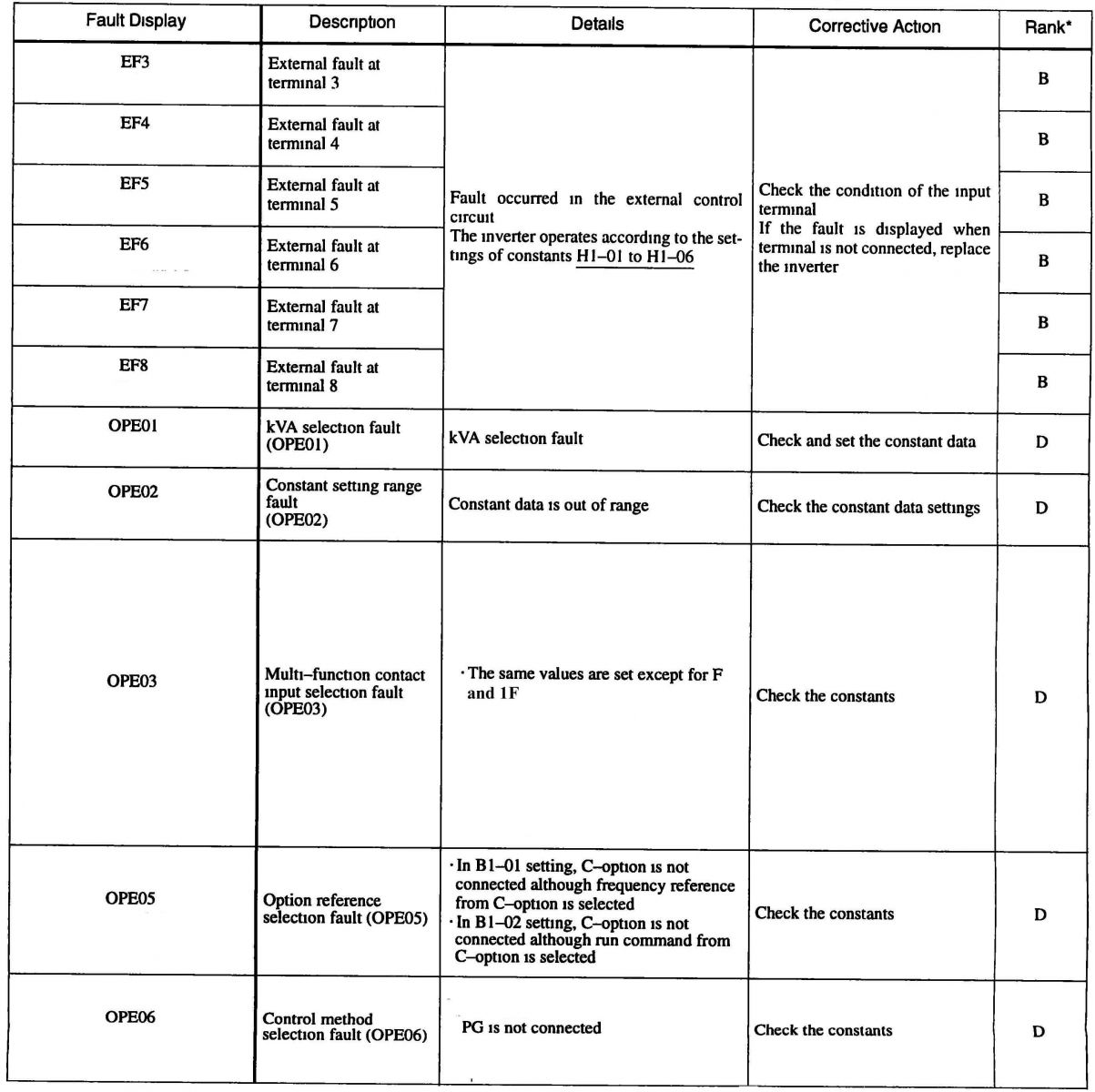

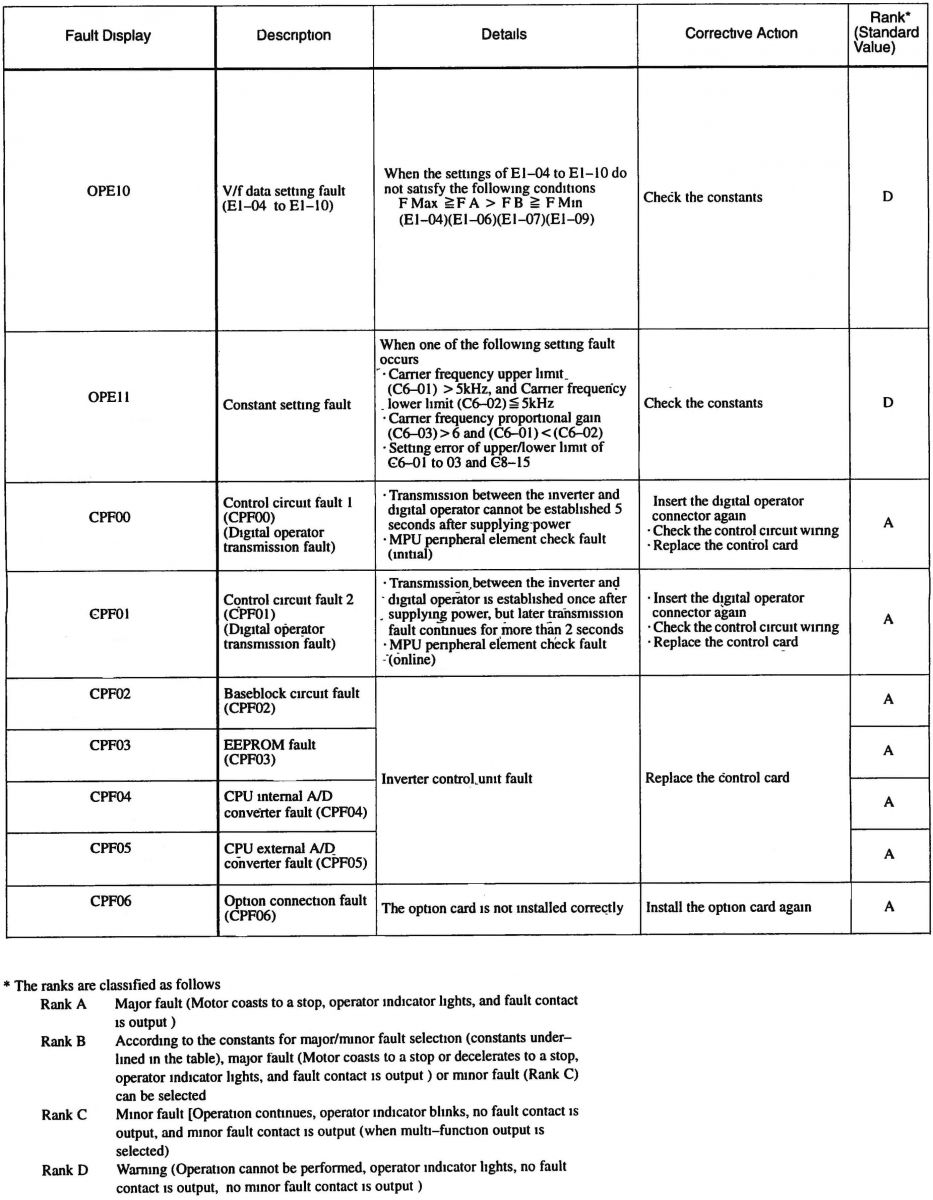

【FAULT DIAGNOSIS AND CORRECTIVE ACTIONS】

- TG700 servo controller IP fault display and the fault contents caused by motor/machine mal-functions and the corrective actions to be taken.

- When TG700 servo controller IP detects a fault, the fault is displayed on the digital operator and actives the fault contact output and the motor coasts to a stop. Check the cause in the table below and tack the corrective actions.

- If the inspections or corrective actions described cannot solve the problem, contact Top Gin representative immediately.

- To restart, turn ON the reset input signal or depress [>RESTART]key or shut OFF the main circuit power supply once, to reset the stop status.

(Download manual of Inverter TG700)