TG300 pan with drive

/

Model: TG300

Inverter

【Performance】

● TG300 IGBT inverter series internally installed a P.I.D. controller is the new generation of inverter designed for industrial machine, machine tools, high torque and smooth operation.

● TG300 is ideal for medium & large horsepower applications.

● TG300 inverter is designed to provide an ultra low noise operation, and contain with several innovative technologies that reduce interference.

● Easy to use, provide practical knob and function keys

● With High-frequency switching technology to reduce the motor running noise substantially. Cost-effective products.

● Complete Protection: Over-current, Regenerative voltage, Motor overheating, IGBT module overheating..

[About TOP GIN] [TOP GIN Milestones] [TG100 Mini Type Inverter] [TG600 Current Vector Inverter]

[TG700 Servo Controller IP] [TG900 Variable Load Drive] [TG1000 High Frequency Inverter]

[Energy Saving Module] [Waterproof Energy Saving Module]

【FEATURE】

[TG700 Servo Controller IP] [TG900 Variable Load Drive] [TG1000 High Frequency Inverter]

[Energy Saving Module] [Waterproof Energy Saving Module]

【FEATURE】

- TG300 inverter Automatically calculating the required torque for loading to achieve the goal of smooth starting.

- High-speed precision, slip compensation, Auto torque boost, overcoming the speed difference caused by load changing.

- Precise sinusoidal control, commercial-current-like current, stable motor operation.

- Saving the power charges by improving the efficiency of motor which operates in light load.

- Maintaining the best operation efficiency of the motor by automatically adjusting the voltage of an operating motor.

- TG300 inverter internally installed with a PID control software which may control and current and air volume without an external PID controller. It is applicable for a wind turbine and hydraulic engine.

- Variety of V / F curve control

- RS-485 communication interface (RJ-45) with MODBUS protocol

- Output frequency 0.1~400 Hz

【APPLICATION】

- Woodworking machines, Conveyer belt , Drawing Machine, Small size milling machine, Packing machine, Elevator, Dumpling machine, Treadmill, Temperature/humidity control fan for agriculture and aquaculture, Edge bending machine, Mixer for food processing, Grinding machine, Drilling machine, Hydraulic lathe, Elevator, Coating equipment, Injection molding machine, Wood machine, Edge bending machine, Elasticize, Air conditioner for large buildings, Water supply system for large buildings, Temperature control of middle/large oven, Webbing loom, Packing machine, Conveyer belt, Fan of drying machine

[About TOP GIN] [TOP GIN Milestones] [TG100 Mini Type Inverter] [TG600 Current Vector Inverter]

[TG700 Servo Controller IP] [TG900 Variable Load Drive] [TG1000 High Frequency Inverter]

[Energy Saving Module] [Waterproof Energy Saving Module]

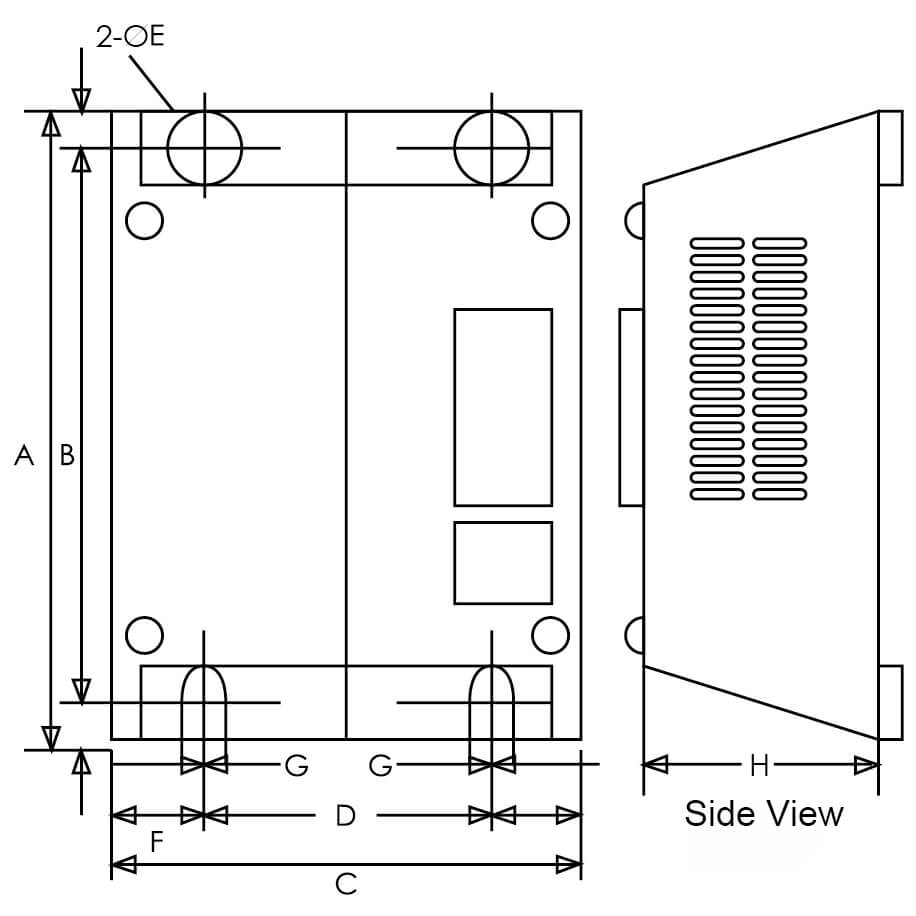

【SPECIFICATION】

(Download specification of Inverter TG300)

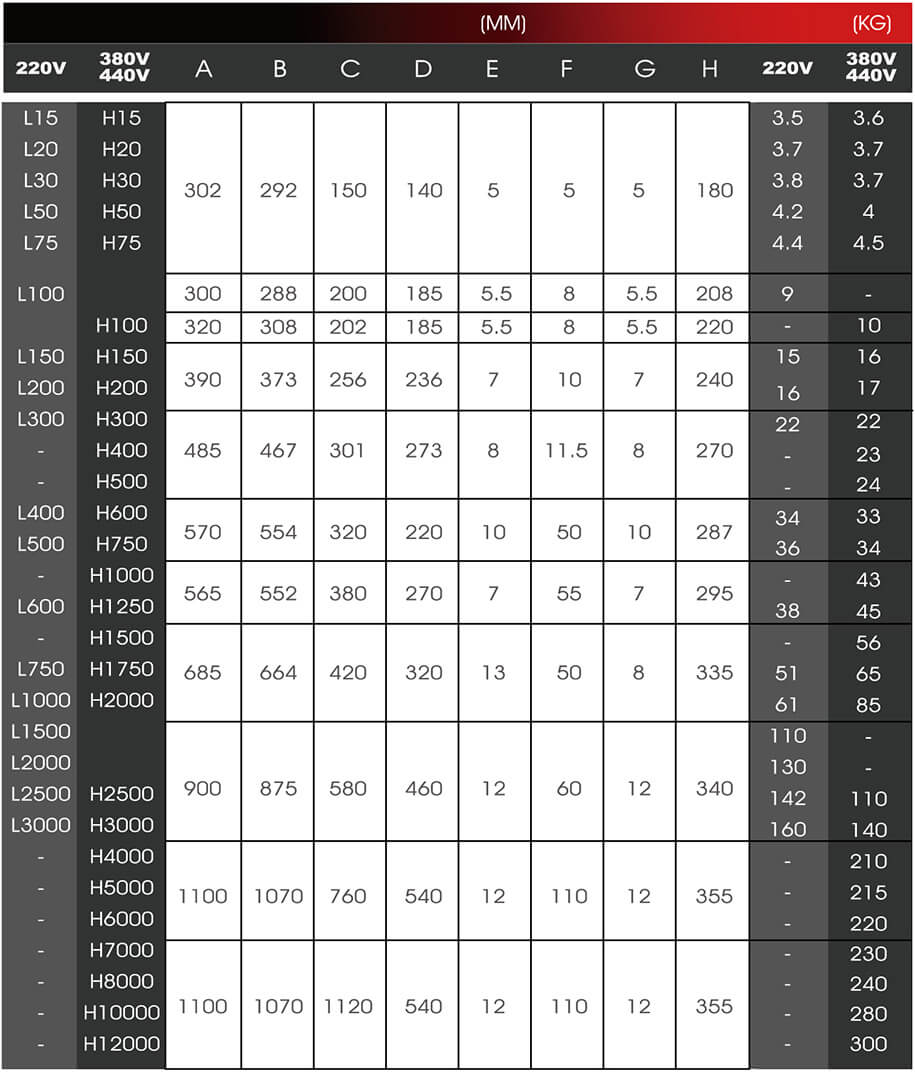

【WIRING】

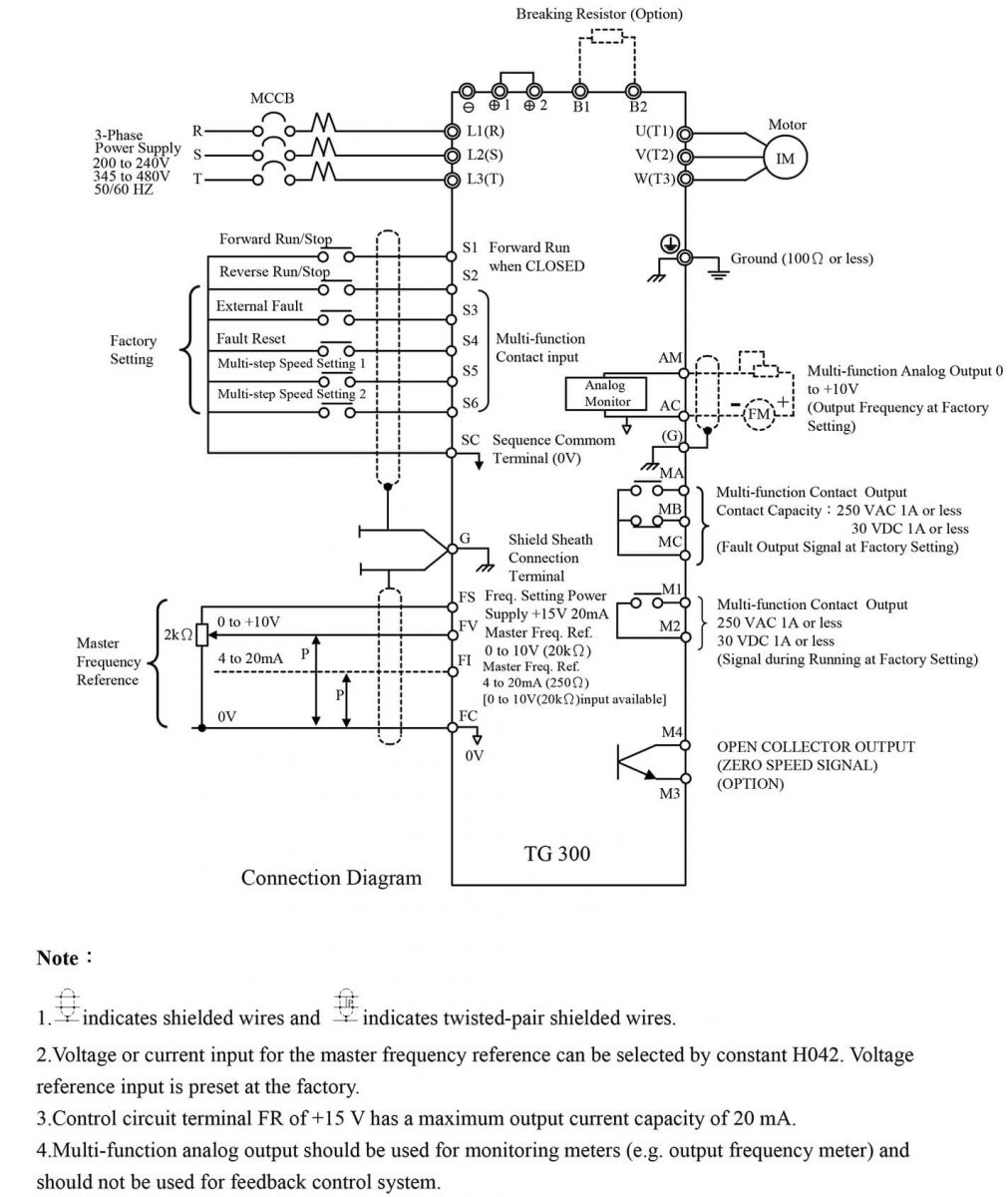

● Below is connection diagram of the main circuit and control circuit. Notify the terminal number when wiring.

.jpg)

【CONNECTION DIAGRAM】

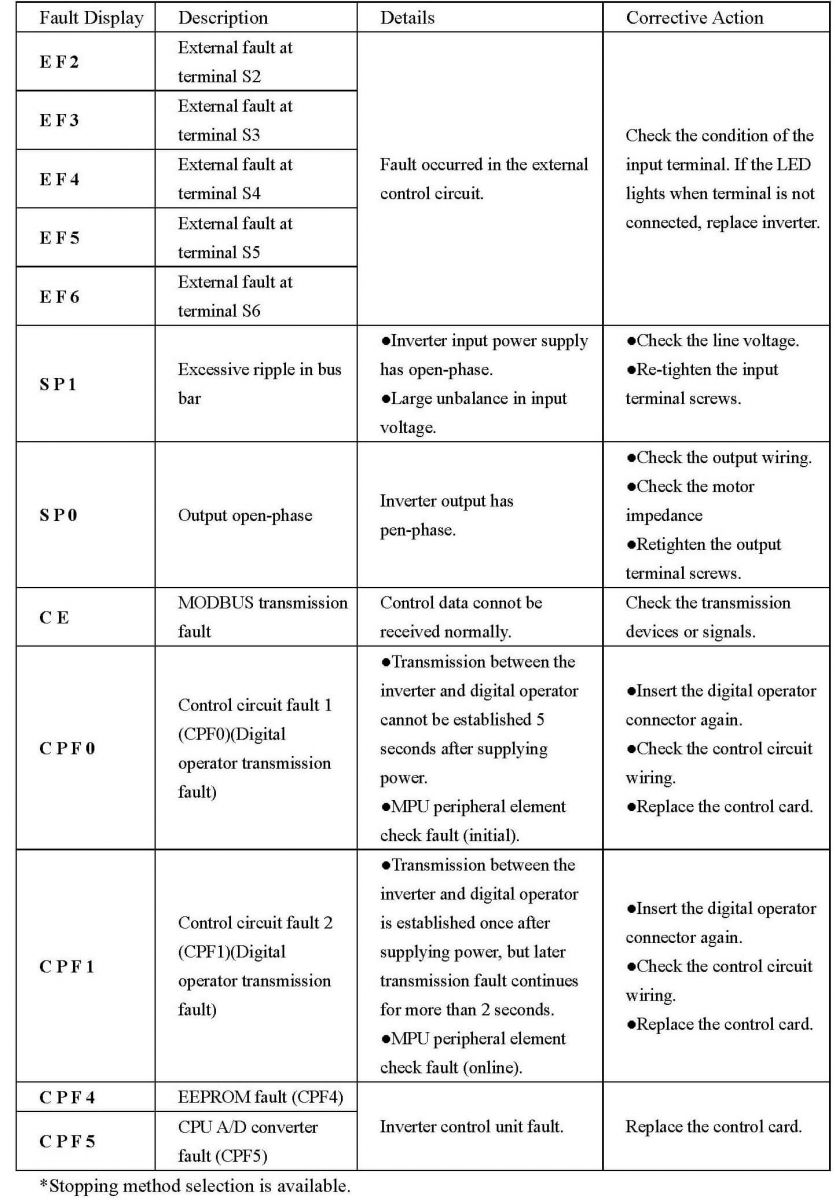

【FAULT DIAGNOSIS AND CORRECTIVE ASTIONS】

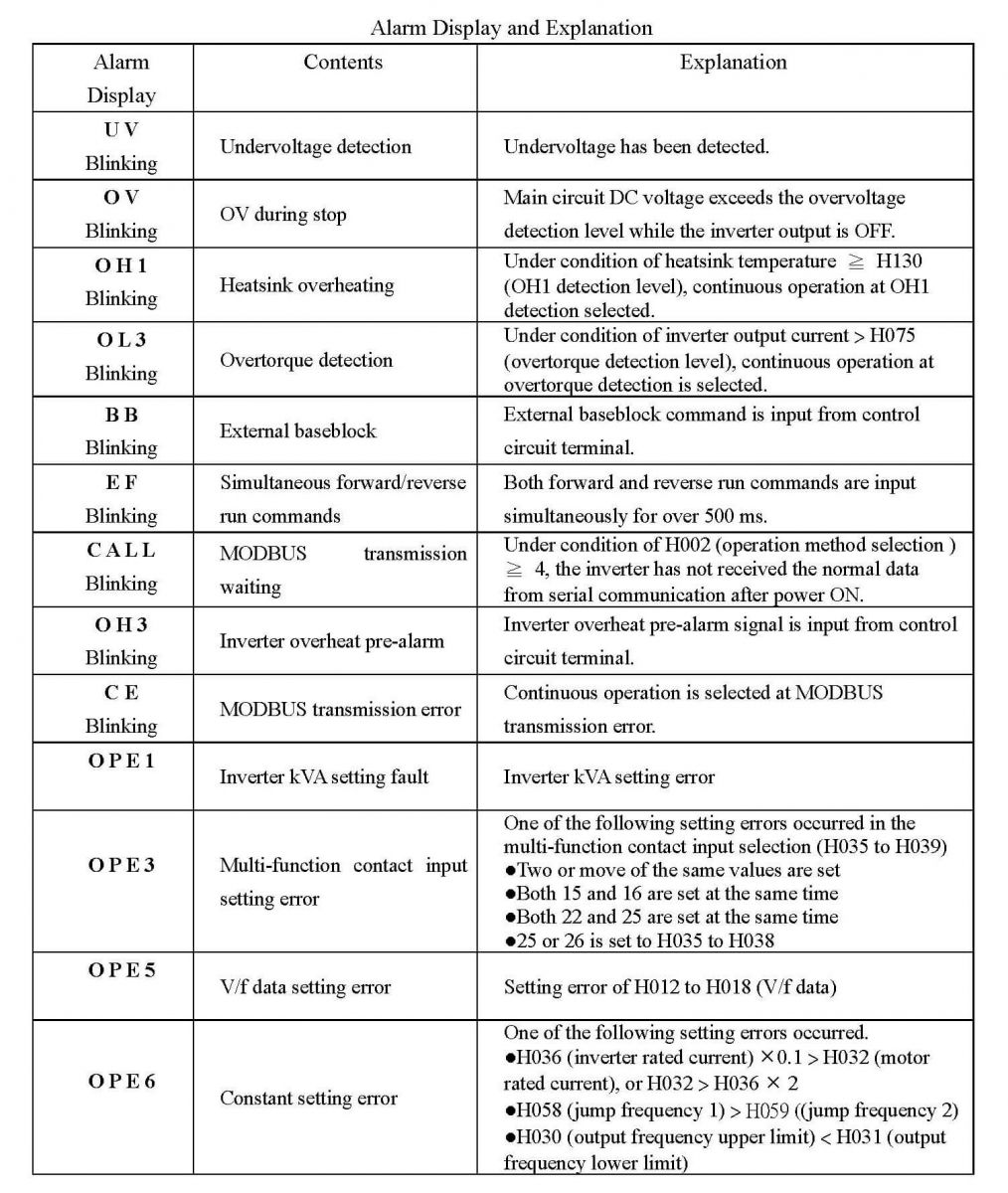

【ALARM DISPLAY AND EXPLANATION】

(Download manual of Inverter TG300)

[TG700 Servo Controller IP] [TG900 Variable Load Drive] [TG1000 High Frequency Inverter]

[Energy Saving Module] [Waterproof Energy Saving Module]

【SPECIFICATION】

| Output characteristics | Standard 220 class | L15 | L20 | L30 | L50 | L75 | L100 | L150 | L200 | L300 | L400 | L500 | L600 | L750 | L1000 |

| Motor (KW) | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 | 55 | 75 | |

| Inverter capacity (KVA) | 2.3 | 2.5 | 4.3 | 6.8 | 9.9 | 13.5 | 19.5 | 24.5 | 37.5 | 51 | 62 | 70 | 85 | 110 | |

| Rated output current (A) | 6 | 8 | 11 | 18 | 26 | 34 | 50 | 65 | 96 | 132 | 163 | 183 | 224 | 330 | |

| Motor rated current (A) | 3.3 | 6.2 | 8.5 | 14 | 19.6 | 26.6 | 39.7 | 53 | 77.2 | 105 | 131 | 160 | 190 | 260 | |

| The maximum output voltage | Three-phase 200~240V (corresponding to input voltage) | ||||||||||||||

| Reated output frequency | 400Hz | ||||||||||||||

| Power supply | Reated onput voltage and frequency | Three-phase 200~240V 50/60Hz | |||||||||||||

| Allowable voltage fluctuation | +10%,-15% | ||||||||||||||

| Allowable frequency fluctuation | ±5% | ||||||||||||||

| Output characteristics | Standard 380/440 class | H15 | H20 | H30 | H50 | H75 | H100 | H150 | H200 | H300 | H400 | H500 | H600 | H750 | H1000 | H1250 | H1500 | H2000 | H2500 |

| Motor (KW) | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | 160 | 185 | |

| Inverter capacity (KVA) | 2.6 | 3.7 | 4.7 | 6.7 | 12 | 16 | 21.5 | 26 | 41.5 | 52 | 62 | 75 | 98 | 130 | 160 | 170 | 230 | 260 | |

| Rated output current (A) | 3.4 | 4.8 | 6.2 | 8 | 14.5 | 21 | 28 | 34 | 54 | 67 | 80 | 98 | 128 | 165 | 206 | 224 | 300 | 340 | |

| Motor rated current (A) | 1.6 | 3.1 | 4.2 | 7 | 9.8 | 13.3 | 19.9 | 26.5 | 38.6 | 52.3 | 65.6 | 79.7 | 95 | 130 | 156 | 190 | 270 | 310 | |

| The maximum output voltage | Three-phase 345~480V (corresponding to input voltage) | ||||||||||||||||||

| Reated output frequency | 400Hz | ||||||||||||||||||

| Power supply | Reated onput voltage and frequency | Three-phase 380~440V 50/60Hz | |||||||||||||||||

| Allowable voltage fluctuation | +10%,-15% | ||||||||||||||||||

| Allowable frequency fluctuation | ±5% | ||||||||||||||||||

| Control characteristics | Control mode | Sine wave PWM mode | |||||||||||||||||

| Frequency control range | 0.1~ 400Hz | ||||||||||||||||||

| Frequency accuracy (temperature change) | Digital signal: ± 0.01% (-10 ~ + 40 ℃) Analog signal: ± 0.1% (25 ℃ ± 10 ℃) | ||||||||||||||||||

| Frequency setting resolution | Digital signal: 0.1Hz Analog signals: 0.06Hz / 60Hz | ||||||||||||||||||

| Frequency output resolution | 0.01Hz | ||||||||||||||||||

| Overload capacity | 150% of rated current for 1 minute | ||||||||||||||||||

| Analog frequency setting signal | DC 0~+10V (20KΩ),4-20mA(250Ω) | ||||||||||||||||||

| Deceleration time | 0.01 to 3600 seconds (acceleration, deceleration time set individually) | ||||||||||||||||||

| Brake torque | About 20% (125% loaded brake controller) | ||||||||||||||||||

| V / F curve | Select from 15 types of fixed V/f patterns or set any V/f pattern. | ||||||||||||||||||

| Protective function | Motor protection | Electronic thermal relay protection | |||||||||||||||||

| Instantaneous overcurrent | Stops at approx. 200% of rated output current | ||||||||||||||||||

| Fuse FusingProtection | The motor stops running after the fuse blows | ||||||||||||||||||

| Overload | The motor stops running if 150% of rated output cirrent at 1 minute | ||||||||||||||||||

| Overcurrent | 220V-Stops when main-circuit DC voltage is approx. 410V 440V- Stops when main-circuit DC voltage is approx. 820V |

||||||||||||||||||

| Low voltage | 220V- Stops when main-circuit DC voltage is approx. 190V 440V- Stops when main-circuit DC voltage is approx. 380V |

||||||||||||||||||

| Instantaneous power-off offset | Setting when playing power outages than 15ms motor free run to stop (external capacitor to 2 seconds) |

||||||||||||||||||

| Overheat | Thermistor protection | ||||||||||||||||||

| Stall prevention | Stall prevention during acceleration and deceleration | ||||||||||||||||||

| Ground protection | Electronic circuit protection | ||||||||||||||||||

| Charging indication | The charging indicator turns on when the DC voltage of the main circuit is over 50V | ||||||||||||||||||

| Environment | Venues | The room is not corrosive or dusty places | |||||||||||||||||

| Ambient temperature | - 10 ~ + 40 ℃ (lock wall type), - 10 ~ + 45 (within the disk take pay type) without a freeze condition |

||||||||||||||||||

| Storage temperature (* 2) | - 20 ~ + 60℃ | ||||||||||||||||||

| Humidity | Below 90% RH (non-condensing conditions) | ||||||||||||||||||

| Vibration | 20Hz below 1G, 20 ~ 50Hz when 0.2G | ||||||||||||||||||

| Protective structure | Wall Mount locking plate inside and take pay type | ||||||||||||||||||

(Download specification of Inverter TG300)

【WIRING】

● Below is connection diagram of the main circuit and control circuit. Notify the terminal number when wiring.

.jpg)

【CONNECTION DIAGRAM】

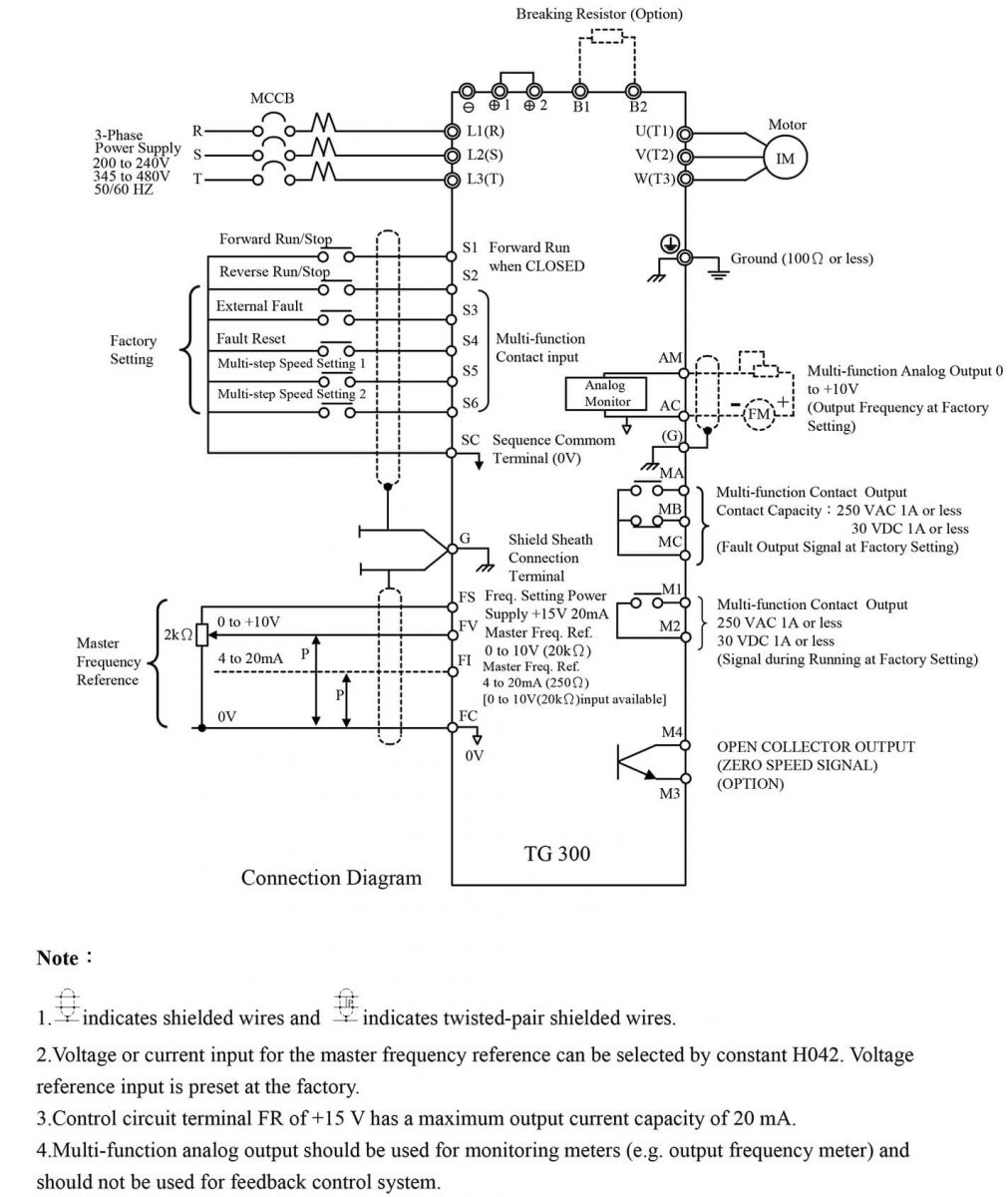

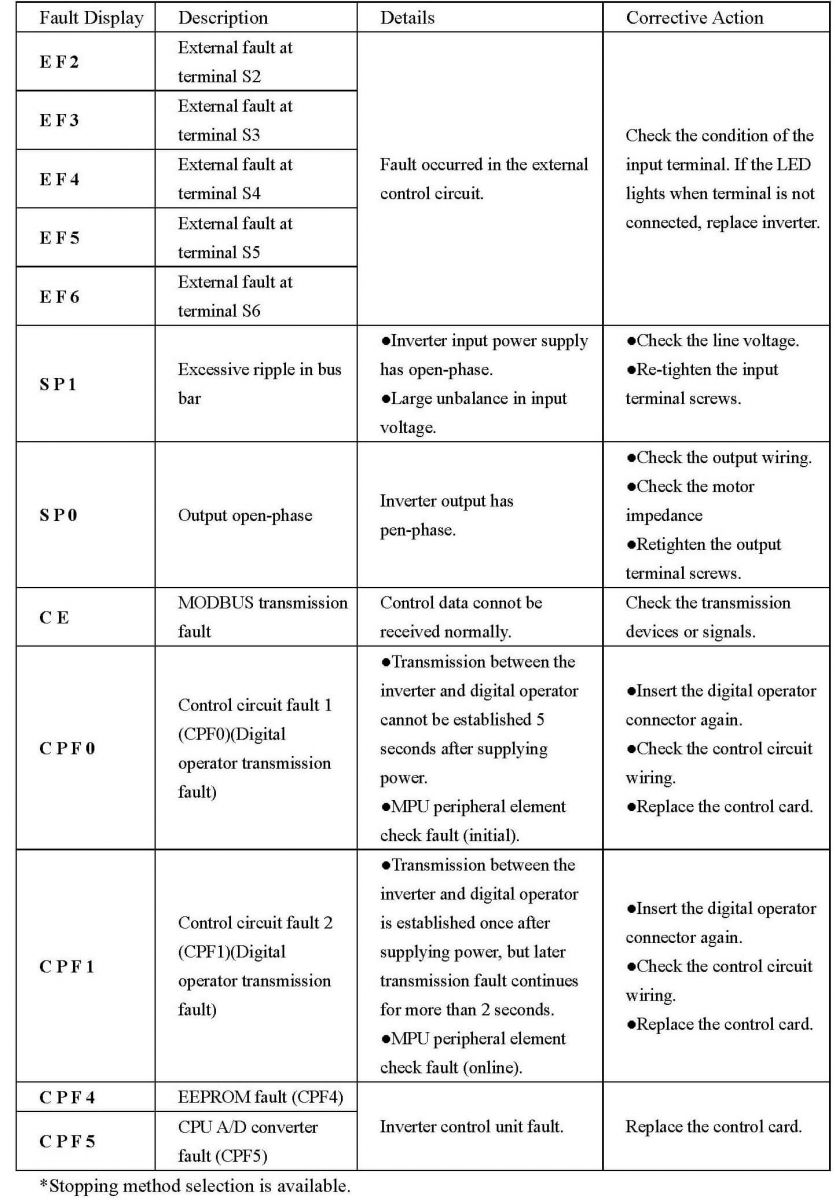

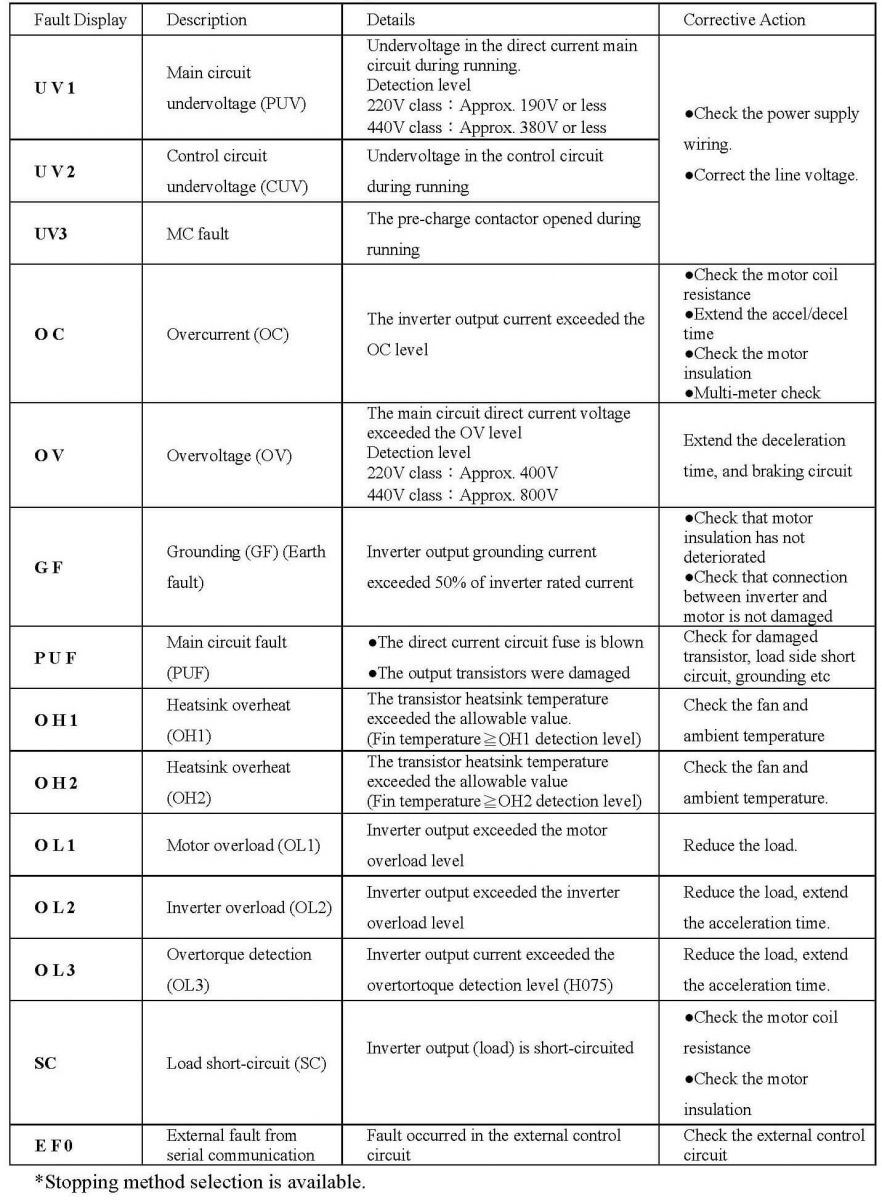

【FAULT DIAGNOSIS AND CORRECTIVE ASTIONS】

- When the TG300 inverter detects a fault, the fault is displayed on the digital operator and activates the fault contact output and the motor coasts to a stop.

- Check the cause in the table below and take the corrective actions

- To restart, turn ON the reset input signal or depress [>RESET] key or shut OFF the main circuit power supply once, to reset the stop status.

- When a forward (S1) / reverse (S2) run command is input, the inverter does not receive a fault reset signal. Make sure to reset after turning OFF the S1 or S2 run command.

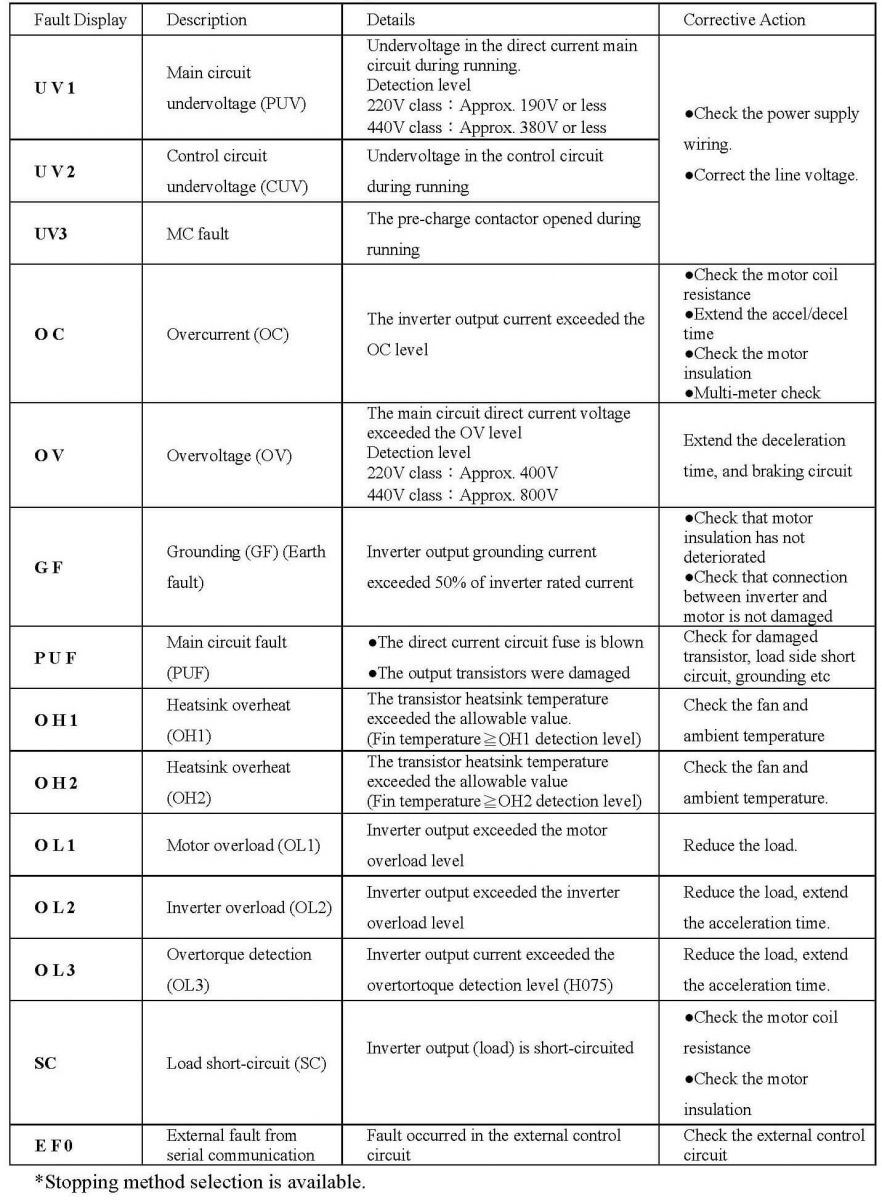

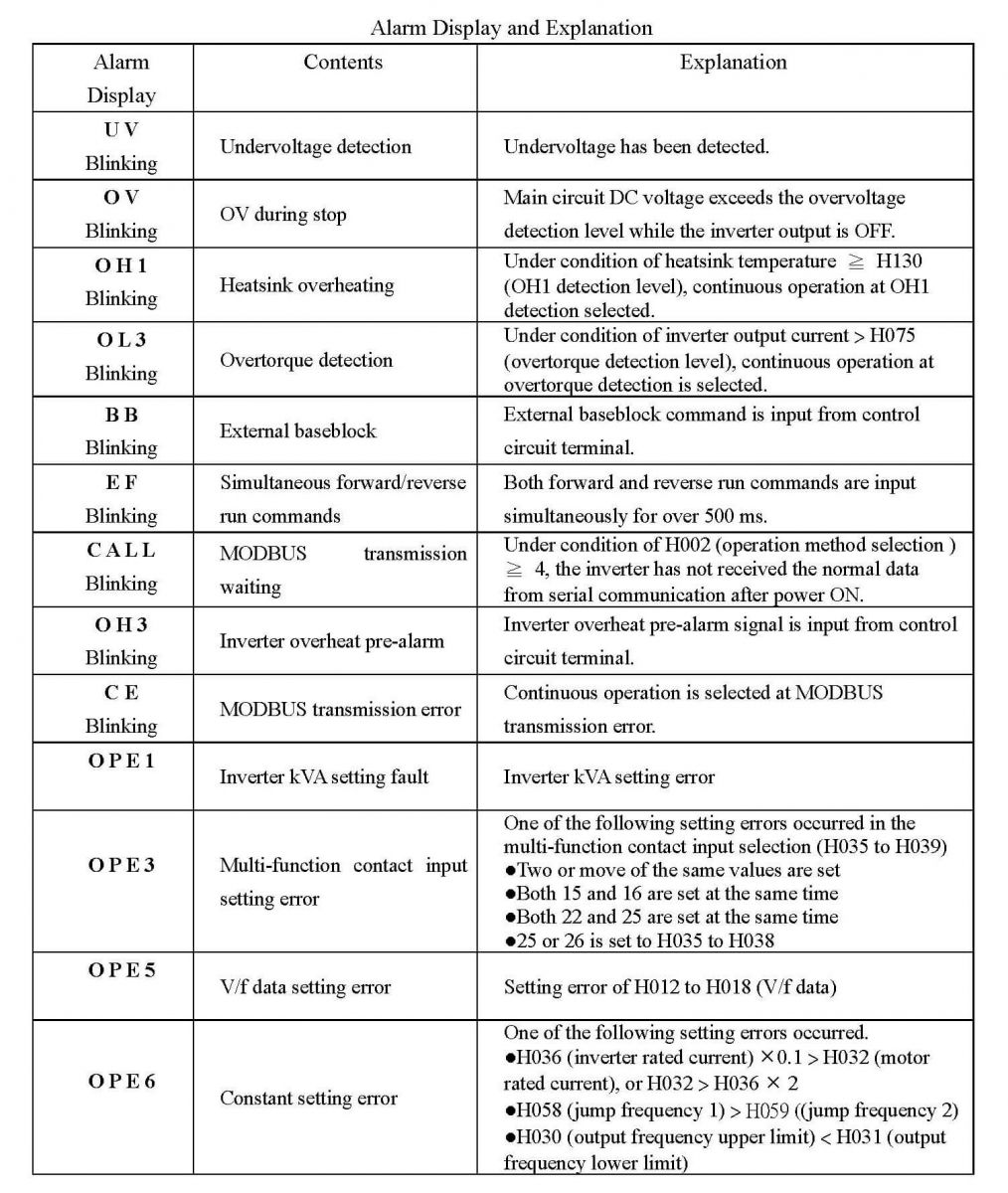

【ALARM DISPLAY AND EXPLANATION】

- As the alarm sounds, TG300 inverter initiates its protection functions and restores to normal operation after the fault causes of multi-function output (MA, MC) are eliminated.

(Download manual of Inverter TG300)